SERVICES

VALUE-ADDED SERVICES

Complete engineering support: Concept design, consultation, and development services.

Material selection: Assistance in choosing materials based on performance and cost.

Prototyping: Visualization and refinement services for product designs.

Steel-to-plastic injection molding conversions: Expertise in converting steel components to cost-effective plastics.

Process-improving secondary equipment capabilities: Solutions to enhance manufacturing efficiency.

Superior quality control: Rigorous standards ensure consistent quality.

Kanban and Just-in-Time inventory methods: Accurate and timely inventory management.

On-time delivery: Timely delivery according to agreed schedules.

EDI capability: Efficient communication and transaction processing.

For custom precision injection molding, trust Calico's comprehensive value-added services. Experience the difference by choosing Calico as your partner.

ENGINEERING SERVICES

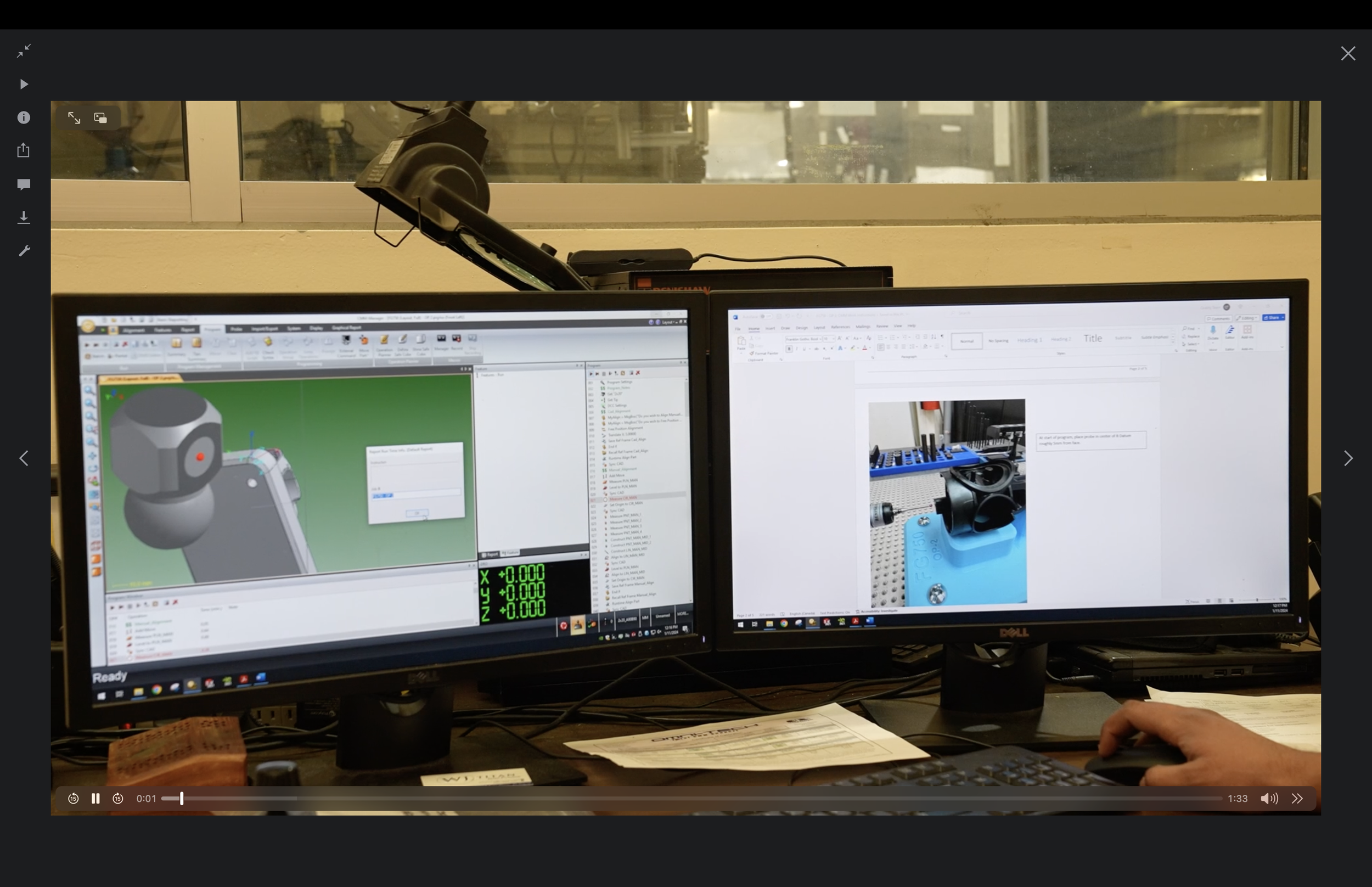

Calico provides in-house engineering support for robust injection molding manufacturability, covering tooling, processing, assembly, testing, GD&T, and inspection requirements. We offer program management services to ensure timely completion of tooling and PPAP, streamlining manufacturing processes. Our cross-functional APQP team ensures flawless production launches with zero-defect expectations.

With AutoCAD and SolidWorks capabilities, we provide detailed design and modeling support. Calico has established relationships with tooling suppliers locally and overseas for competitive pricing and reduced lead times. We collaborate with raw material suppliers for critical support and conduct molding analysis.

We work with automation suppliers to implement poke-yoke solutions for assembly and testing processes. Quality and precision are ensured through partnerships with inspection suppliers offering complete 3D scanning capabilities. Additionally, we provide variable and attribute gauging solutions during production.

Overall, Calico offers a comprehensive range of services and strategic partnerships for efficient and high-quality product development and manufacturing.

MATERIAL SELECTION / PLASTIC

With our engineering team's extensive experience and deep knowledge in injection molding, we are highly qualified and enthusiastic about assisting you in determining the optimal material for your unique injection molded product.

If you are in the process of developing a new injection molded product and unsure about the most suitable material, we can provide expert guidance on all relevant selection criteria, including any regulatory considerations that must be met.

In the event that the material currently employed in your existing injection molded product is not meeting your expectations, we can assist you in choosing a more appropriate alternative that fulfills your requirements. If necessary, we can also present you with various design options to explore.

Calico is your comprehensive solution for all your custom injection molding needs, offering an extensive selection of materials to meet your requirements. What sets us apart is our unique capability to work with both plastic and rubber, making us a versatile supplier in the industry.

We offer a wide range of routinely employed plastic materials, including:

ABS

Acetal

Nylon

Glass-filled Nylon

PBT

PEEK

Polycarbonate

Polyester

Polyethylene

Polyphenylene Sulfide

Polyphthalamide

Polypropylene

Polystyrene

Thermoplastic

PRODUCT DESIGN

Calico goes beyond mere fabrication of custom injection molded plastic with tight tolerances. We provide comprehensive design support for even the most complex projects, catering to any industry or application. Our engineering team possess extensive experience in designing and manufacturing custom injection molded products.

Furthermore, Calico's design expertise extends to engineered-grade thermoplastic components and assemblies, utilizing both filled and unfilled resins. This means we can work with a wide range of materials to meet specific requirements.

If you require design support for your custom injection molded parts or components, Calico is the company to contact. Our knowledgeable team is ready to assist you in bringing your ideas to life and delivering high-quality solutions tailored to your needs.